Manage and report production with less effort, errors and paperwork.

Take a quick inventory of everything that happens from the time you receive a customer PO until you send them an invoice. What goes wrong in your process?

MillTools solves your problems and helps you operate more profitably.

Identify and solve production quality problems FAST.

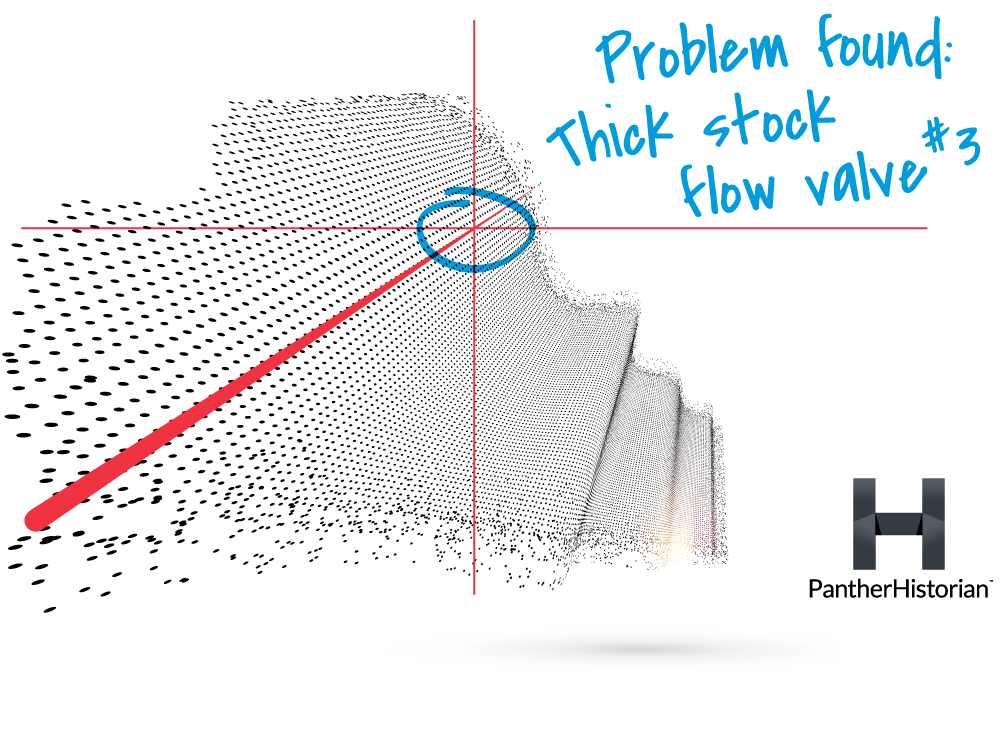

Capture data from sources such as continuous process variables, scanner quality profiles, discrete lab test data and events which occur at different times during production. ProcessAnalyzer retreives data from QCS, MES, DCS and other databases, then plots the data graphically on a contiguous timeline in 2D and 3D, so you can quickly identify cause and effect of production quality issues.

Upgrade your QCS without ignoring the rest of the mill’s needs.

It was time to upgrade your quality control system ten years ago, but QCS isn’t the mill’s only need. A new refiner or a roof that won’t leak over the paper machine are still on the list.

PantherQCS offers paper mills excellent paper quality measurement, low cost of ownership and long life without breaking the bank.

Our Professional Services engineers and technicians handle installations, maintenance and repairs

Our most indispensable solution. Panther Professional Services technicians are insurance, that your systems turn in a profit-making performance month after month.

They are in our customers’ mills every day, performing maintenance and making repairs. Most importantly, they find and prevent problems BEFORE they happen. Our technicians become an extension of your own team — people you know will come through for you and care about the same things as you and your team.