Manufacturing Execution

Manage orders, scheduling, production, inventory, shipping and invoicing with one easy-to-use and powerful solution. See how much MillTools® will make and save you.

QCS and Machine Control

Give your quality control system a new life. Up your paper quality, reduce your cost of ownership and extend the life of your system with PantherQCS™.

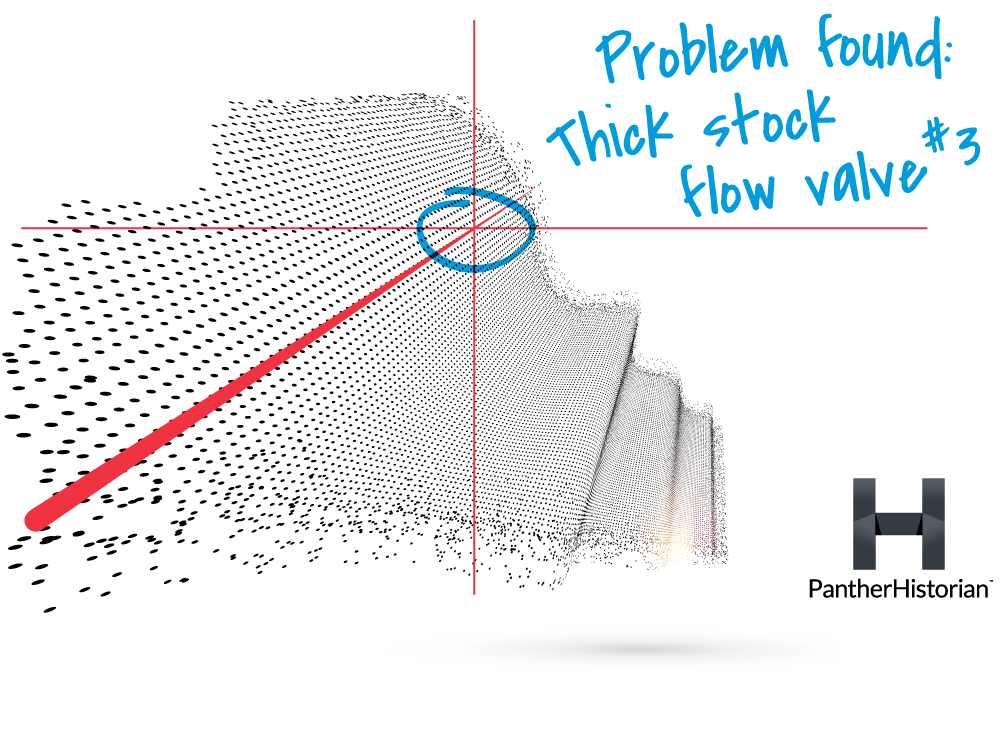

Data Management and Reporting

Panther Historian™ gives paper mills powerful analytical tools, dashboards and reports to unleash insights and make timely decisions.